Views: 0 Author: Site Editor Publish Time: 2025-11-14 Origin: Site

Demand for durable, hygienic interiors (post-pandemic hygiene & longevity concerns).

Sustainability pressure: recyclable materials outperform short-life plastics.

Design continuity: consumers and specifiers want matching interior and exterior finishes — HPL can be the common material.

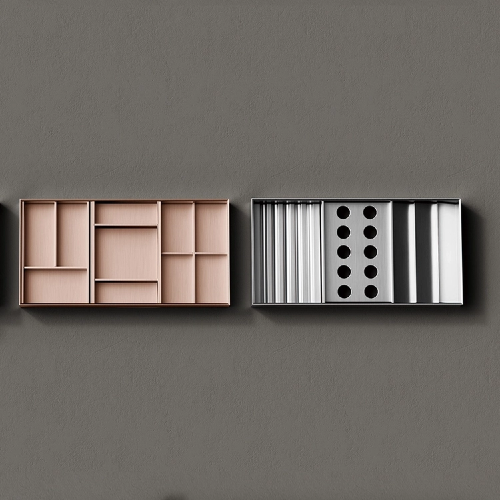

Modularization & customization: HPL works well with CNC cutting and precision joinery for bespoke drawer systems.

Bathroom cabinet interiors & drawer organizers (highest near-term adoption).

Hospitality in-room accessories and amenity trays (durability & cleanability are priorities).

Kitchen drawer inserts and under-cabinet systems (heat and scratch resistance matter).

Over the next 24–36 months, expect:

Increased spec writing for HPL in project tender documents.

More OEM lines adopting HPL for interior accessory ranges.

Higher demand from renovation and retrofit sectors, where HPL’s non-disruptive installation and low maintenance are attractive.

FIESONO leverages HPL in Luanbird and Chongming to deliver products that match these market demands: premium look, hygienic performance and modular flexibility — all at competitive price points.

HPL adoption is not a fad — it is a structural improvement in how cabinetry and storage are specified. Partner with FIESONO to capture this growth.

CTA: Contact our business development team for market samples, pricing tiers and pilot programs.